Ford-Otosan-Die-Workshop

Turkey's highest capacity die manufacturer

With more than 60 years of experience, Ford Otosan Die Workshop single-handedly finalizes all processes of aluminum and sheet metal part dies for global brands, from design to quality control, from engineering to production.

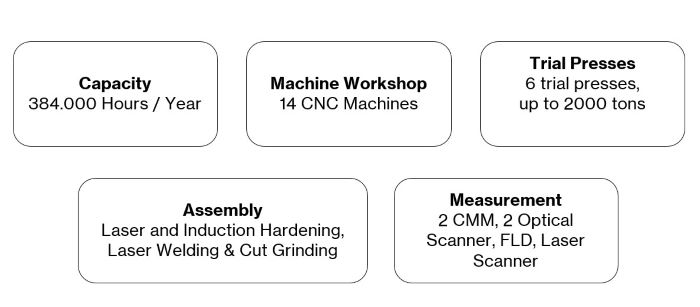

With its strong project management and experienced expert staff, Ford Otosan Die Workshop, which produces Türkiye's fastest and highest quality doors, can produce 160 medium and large dies on turnkey basis with an annual production capacity of 384 thousand hours at its location in Gölcük, while this number increases up to 400 with external resources.

All processes from Design to Production in one hand

Ford Otosan Die Workshop, with its experienced expert staff, manages all processes from die design, feasibility, engineering, testing and production.

.jpg)

90% Dimensional Success Ratio

Thanks to its know-how in design and manufacturing, it identifies and solves potential problems at the design stage. Increases productivity with verified solutions using advanced technologies such as full-cycle simulations, virtual manufacturing and surface analysis. Over 90% dimensional conformity is achieved in the first parts coming out of the dies produced.

Engineering Process

At Ford Otosan Die Workshop, engineer processes start with feasibility simulations. With the contribution of these results to the product development process, areas that are not applicable are identified and alternative solutions are proposed to guide this process. While errors are minimized with the springback analysis performed during the design phase, panel quality is increased with surface analysis and virtual manufacturing methods, and the design is adapted to production processes.

Project Management

Ford Otosan Die Workshop, the first and only die manufacturer in Türkiye to be able to track work and performance with real-time data, realizes much faster, more transparent and higher quality production with its agile, innovative project management process fed by digital tools.

Production Details

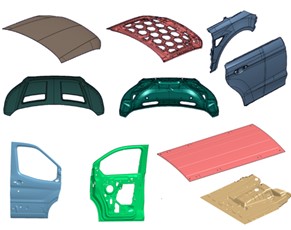

Which parts do we produce?

In our workshop, we have been successfully producing many different large and medium-sized parts for 60 years. We specialize in die sets: Hood, Fender, Doors, Body Side Outer/Inner, Roof, Floor, Door Frame ve Chasis.

Our Most Important Value: QUALITY

We shorten the production process with our digitally assured engineering strategy. By achieving over 90% dimensional fit between the design and the first manufactured part, we minimize error and pave the way for more sustainable production.

Which Vehicles Are We In

We manage all pressing operations of the Ford Transit and Ford Trucks family, including facelifts, together with our service teradicators. In addition to Ford's commercial, heavy commercial and passenger vehicles, we continue to produce die for many different brands..

Our Customers

Contact Information

E-Mail: toolanddie@ford.com.tr

Phone: +90 262 315 50 00 (Ext: 6411)