History

The First Ford Dealership

The story of Ford Otosan began on 31 March 1926 when Vehbi Koç registered his business with the Ankara Chamber of Commerce as ‘Koçzade Ahmet Vehbi Business Establishment. Later, he was elected as Head of the Administrative Board of the Ankara Chamber of Commerce, and in 1928 started to sell automobiles in the first Ford dealership.

The First Dealership in the World with the Rights of Assembly

Our founder Vehbi Koç was invited to America after our Ankara dealership won a competition arranged by Ford between 34 dealerships in the Middle East. He took with him a project for an assembly plant and a letter of support from the Prime Minister, Adnan Menderes, and gained the right to set up an assembly factory as Dealer Assembler, a world first. The agreement covered all dealerships in Turkey, and allowed for 85% of the goods produced in the factory to be marketed by the Koç Group.

The First Assembly Factory Founded by Otosan-Ford Partnership

In 1959 we founded Otomobil Sanayi - Otosan A. Ş. and laid the foundations of our first assembly factory. It was the first automotive company founded under Industrial Planning, and with it we started our activities of contributing to economic development.

Production Starts at the İstanbul Factory

In 1960, assembly and production of the Ford Consul automobile and the Ford Thames truck began at our İstanbul factory.

The First Minibus Rolls off the Assembly Line

In December 1961, Otosan’s first minibus, the Thames 800 (T-800) — the predecessor of the Transit — rolled off the assembly line. In the same year, assembly began of the Thames Trader, the predecessor of the D series and Cargo trucks which we would produce in later years.

Production of the D1210 Truck Begins

Production of the D1210 Ford truck began in 1965, and continued for 17 years. A total of 56 124 D1210s were produced in 1983.

Production of the Anadol, Turkey’s First Local Automobile

Thanks to our experience gained by being at the forefront of assembly production in the automotive industry, our engineering success and our determination, we succeeded in producing the first local car to meet Turkey’s needs, the Anadol series. We were the first company to be able to produce our own brand, placing ourselves ahead of other assembly producers.

The first Anadol left our factory doors in 1966. It was followed by 93 188 more, and production continued until 1984. Considered a good vehicle by the standards of the time, the Anadol resulted in growth and development in the emerging automotive supply industry.

Transit Production Starts

Production of the Ford Transit, in later years to become one of our flagship products, began, two years after the start of Transit production by Ford UK. With the start of production of the Transit in 1967, we pioneered a new era in the sector of light commercial vehicles.

The First License Agreement between Ford and Otosan

The license agreement which we signed in 1977 was a turning point in the relationship between the Ford Motor Company and Otosan. With this agreement, we as Otosan acquired the rights to the production and sale of the Ford D1210 truck and the Transit series in Turkey, and permission for local production of engines. We also obtained the rights to the production and the manufacture of Anadol and Transit engines, and back axles and gearboxes.

Founding of the İnönü Factory in Eskişehir

In 1979, the foundations were laid of our İnönü Factory in Eskişehir, and in 1982 production of the D1210 truck began there for the first time. The factory was officially opened on 7 July 1986 by Prime Minister Turgut Özal. The İnönü Factory, opened to increase local production, to reduce the need for foreign exchange to a minimum and to increase the quality of production, was also aimed at increasing our production capacity of commercial vehicles.

Production of Ford Cargo

After nearly 20 years of production of the D series truck, Ford took a new step in 1982 with the introduction of the Cargo to the market. Only one year later, we began production of the Ford Cargo truck at our İstanbul factory

Production of the Ford Cargo is Moved to the İnönü Factory

In 1983, after beginning production of the Ford Cargo series and these trucks becoming market leaders, we transferred the commercial units section from İstanbul to our İnönü Factory in Eskişehir. From September 1984, all production of the Ford Cargo series took place here.

30% of Otosan’s shares Acquired by Ford

In 1983, the Council of Ministers gave the Ford Motor Company the right to acquire a 30% share in Otosan A.Ş. The agreement was signed on 6 October 1983.

The First Ford Taunus off the production line

In the wake of the partnership between Ford and Otosan, talks began for the production of a sheet metal bodied automobile instead of fiberglass. At Otosan, as well as continuing production of the Anadol, we also began work on satisfying changing customer needs. Soon after the partnership agreement came into operation, work on making a steel-bodied automobile was accelerated. Templates brought from Ford’s factories in the UK and Germany were installed in our İstanbul factory where assembly lines were completely changed and a modern paint shop was constructed. On 12 September 1985, the first “Best Local” Ford Taunus rolled off the assembly line, with our Honorary Chairman, Rahmi M. Koç, at the wheel.

Foundation of Nasoto

Nasoto, founded in 1985, acquired the general distribution rights of Otosan and Ford Motor Company products and spare parts. Nasoto played an extremely important role in setting up a network of sales and service facilities to meet the needs of the developing market.

Production of the ERK, Turkey’s first diesel engine

Turkey’s first diesel engine, the ERK, was produced at our İnönü Plant. The ERK engine was first used in the Anadol Pickup, which was offered to the market also in that year. 1986 was a year of firsts when we began to export engine parts to Ford Germany and to produce “Industrial Engines” for the industry as Otosan.

The New Cargo is offered to the Market

At the beginning of the 90s, our leadership of the commercial vehicle market was confirmed when the 20 thousandth Cargo rolled off the line at our İnönü Plant in 1991. The Cargo 2520 truck with the 185PS engine which we had developed was also offered to the market that year. As a result of these successes at our İnönü Plant, Ford won the highest prize for quality, the Q1 Preferred Quality Award, which was presented at a ceremony in London in 1993.

With the handover by the Koç Group of the company shares of Nasoto in 1992, 88.85% of the company’s capital belonged to Otosan A.Ş., and its name was changed from Nasoto A.Ş. to Otosan Pazarlama A.Ş. (Otosan Marketing Inc.) The first steps had been taken in developing a new understanding of sales, after sales service and marketing.

Production of the Ford Escort

After production of the Ford Taunus ceased, we began to produce the Escort, Ford’s popular model throughout the world. Production of the Ford Escort started after renovation of our Istanbul Factory, and we demonstrated our success among local automobiles with the production of 59 389 vehicles by the end of production in 1999.

Changeover from Otosan to Ford Otosan

On 27 June 1997, Ford and Koç Holding equalized their shares with an agreement signed in Cologne. This decision was endorsed and brought into operation at an Extraordinary General Assembly of Otosan one month later on 24 July, and on this date Ford Otomotiv Sanayi A.Ş., that is Ford Otosan, was born. Each group had equal shares: 41% each, with 18% held publicly. The change from Otosan Pazarlama A.Ş. to Ford Otosan was completed with this agreement. In this way, Ford Otosan became a single large company with responsibility for production, marketing, sales and after sale services.

Spare Parts Distribution Center is Established-55000

In 1998, our Ford Otosan Spare Parts Distribution Center was opened, making it one of the largest investments of its kind in Turkey. Our Kartal Spare Parts Distribution Center today has a covered area of 25 000m2, and at any time has a stock of around 55 000 different kinds of spare part. It serves 192 sales points in Turkey and 58 in 50 other countries, and has become Turkey’s largest automotive spare parts center.

Opening of the Kocaeli Plant

Production at our İstanbul Factory, which had begun with assembly in 1960 and had continued without a break for forty years, was ended in December 2001. Our new Kocaeli production area project was brought to life in 1997 for the production of Ford’s new light commercial vehicle and the Transit with an investment of 650 million dollars, making it the biggest investment made at one time in the Turkish automotive sector. The foundations of our Kocaeli plant were laid in 1998, with the full support of the 9th president of the Turkish Republic, Süleyman Demirel. The opening ceremony of the Ford Otosan Kocaeli Plant took place in April 2001 in spite of the economic crisis which Turkey was experiencing at the time, with the participation of Mesut Yılmaz, Rahmi M. Koç and Jack Nasser.

Production of the Transit Connect

After the start of production of the new Transit at our Kocaeli Plant, around 100 Ford Otosan engineers who had been gaining experience in the United States between 1998 and 2000 moved to the Kocaeli Plant, and in as short a time as six months, serial production of the Transit Connect was started there and it was the only production center for the Transit Connect in the world. The first vehicles exported to Europe were loaded on to two Ro-Ro ships at the newly-opened Yeniköy dock, bound for the UK, at a ceremony on 5 July 2002.

Our Kocaeli Plant was awarded the title of “One of the Best Ford Plants in Europe” for six years consecutively from 2002, after which the title became permanent. After 2009, Ford of Europe instituted a new inspection system and it was decided not to issue any certifications.

2002: Ford Otosan’s First Market Leadership

As Ford Otosan, our market leadership would continue in the following years without a break, and in 2002 we achieved the sale of 24 171 vehicles.

The Connect Selected as International Van of the Year

The Transit Connect, produced only in our Kocaeli Plant in the world, was awarded the title of 2003 International Van of the Year after only one year of serial production.

In the same year, the Ecotorq engine, a heavy-duty diesel engine and the first engine to be designed entirely in Turkey, was produced at our İnönü Plant and received the Jury Special Award in 5th Technology Awards.

One millionth vehicle produced

In 2005 we produced our one millionth vehicle, a Ford Transit. It rolled off the production line in a ceremony with Ford Otosan Chairman Rahmi M. Koç and Ford of Europe President Lewis Booth.

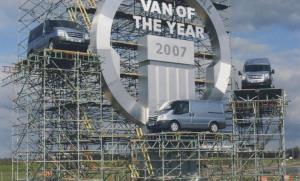

The Ford Transit is selected International Van of the Year

In 2007 we were the leader of total market for the seventh time, and this time the Ford Transit won the prize of International Van of the Year. The success of our products on the European and other markets added to our success in the internal market and made Ford Otosan a leader on world markets.

Gebze Technology Center Opens TUBITAK

In September 2007, the opening took place of our Technology Center in Tübitak’s Gebze Technopark, with the aim of developing the newest products and the newest technology in order to gain preeminence in worldwide competition by continually building on the success of Ford Otosan in the domestic and worldwide markets.

The Ford Connect is the First Vehicle to be Exported to the USA

In 2009 Ford Otosan was the leader of total market for the eighth time and were exporting to more than 60 countries on five continents. In that year we took a new step forward as the first Turkish automotive company to export to the USA, the home of the automotive industry and Canada. We achieved one-sixth of the total export of Turkey to the United States, about 30 thousand Transit Connects, at one stroke of the pen.

The Connect is North America’s Van of the Year

The Transit Connect, produced at our Kocaeli Plant, wins the Van of the Year award in Europe in 2009 and in North America in 2010.

The Six Millionth Transit is Produced

Along with all our dealer network and suppliers, in 2010 we celebrated the 50th anniversary of the foundation of Ford Otosan, and the six millionth Ford Transit produced in the world rolled off the production line in Turkey with a ceremony.

Ford Otosan in World Ranking

We had the second best year in our history: Ford in Turkey had the highest market share of any country in Europe, and inside Turkey, Ford was the highest-selling brand in 63 provinces. Compared with the previous year, our production increased by 40%, and we raised our export figures by 37%. The value of the company was 2.4 billion dollars in 2000, and we raised this by 46% to 3.2 billion in 2010, earning us a place on Forbes list.

Connects used as taxis in New York

With ten years as market leadership and strong sales performance in the Turkish market, in 2011 we succeeded to be the country where Ford has the highest market share exceeding 39 European countries, especially the UK. That year Transit Connects started to be used as taxis in New York.

In 2012 we exported 205 thousand Connects to Europe and 100 thousand to America. Production of the Transit Connect, which was so successful in Europe and America, was moved from Turkey to Spain’s Valencia plant in line with Ford’s One Ford policy, and production of the Transit Connect at our Kocaeli plant came to an end in December 2013.

Investment Year is Announced for Commercial Vehicles

Having announced that we would make an investment of over one billion dollars between 2011 and 2014, we signed the biggest ever investment for a new model in the Turkish automotive sector in 2011, with an investment of 630 million dollars for the new generation Transit. The first products of this investment, the Transit Custom and the Tourneo Custom models, went into mass production on Monday 23 July 2012. Currently, our Kocaeli plant is the sole production center in the world of the Ford Custom model. After our new generation of Transits, we also went into production with the new model named Courier, brought about with an investment of 500 million euros including a new plant.

Signing of the Global Truck Agreement

With the signing of the Global Cargo Agreement with Ford Motor Company in 2011, we gained the rights to assign the distributors and dealerships for Ford Trucks in 59 countries. With this agreement, Ford Otosan became a global product development and planning center for Ford heavy commercial vehicles and their diesel engines.

Ali Y. Koç Becomes Chairman of Ford Otosan

Ali Koç Becomes Chairman of Ford Otosan

Foundations are Laid for the Yeniköy Plant

In 2012 we laid the foundations of our third plant which would go into go into service in 2014. Our Kocaeli Yeniköy Plant, built with part of a one billion dollar investment, is the sole world production center of the Courier, putting Ford into a new segment of the light commercial vehicle class.

Transit Custom and Tourneo Custom Introduced to the World Market

In 2012, the Transit Custom and the Tourneo Custom were introduced to the world market. The Transit Custom was chosen 2013 International Van of the Year, gaining the highest number of points ever from the members of the jury.

Start of Production of the Ford Cargo 1846T

Production began of the Ford Cargo 1846T, developed for the world market by engineers working at Ford Otosan. The vehicle gained third place in the vote for Truck of the Year 2013.

Twelve Consecutive Years as Leader – a Record

Our long-established and strong sales network in Turkey made us the leader in commercial vehicles in the domestic market, and between 2002 and 2013 we were the most-selling automotive brand in the whole market.

Export of Technology to China

In 2013 we made progress as an important brand on the world markets, when the distribution of Ford Cargos in 59 countries was gathered under the name of Ford Trucks. We signed a technology licensing agreement for the Ecotorq engine, for which we had the intellectual property rights, to be produced in China for use in JMC vehicles. In line with our strategy of diversifying our export market, we began to export vehicles to Mexico.

Engine Test Center of the Year at Kocaeli

Our engine test center at Kocaeli went into operation in 2012, and won the prize of Engine Test Center of 2013 at an international level, receiving commendations for high technology and efficiency.

Start of Production of the Seventh Generation Ford Transit

In 2014, at our Kocaeli Gölcük plant, the lead production center of the Transit in the world, production began of the seventh generation Ford Transit, and in a short time it was introduced to the world market.

The Sole Production Center of the Ford Courier

The only production center in the world of Ford’s new light commercial vehicle the Courier, our Yeniköy Plant, was opened on 22 May 2014. The plant, built with a production capacity of 110 thousand units and completely disabled-friendly, was equipped with high technology and environmentally friendly applications.

With our Yeniköy plant, we were certified by Ford of Europe as putting Global Ford Production systems into operation in a fast and efficient way and as the factory best operating the system

Attaining the Highest Production Capacity in the Turkish Automotive Industry

As Ford Otosan, we made the biggest investment in the Turkish automotive industry by spending nearly 1.6 billion US dollars between 2011 and 2014. Following this investment, we became Ford Europe’s production center for commercial vehicles. In only four years, the total capacity of our Kocaeli Plant rose from 140 thousand to 320 thousand, and after 2014 it rose to 400 thousand, heavy trucks excepted. With a capacity of 415 thousand including heavy trucks, we now have the highest installed capacity in the Turkish automotive industry.

Opening of Exhaust Emission Systems Test Center

We brought into service an exhaust emission systems testing center at our Gölcük R&D Center. This was Ford’s first such facility in the world providing this service.

Opening of the İnönü Engine Testing Center

At our Eskişehir İnönü Plant, we opened our second engine test center, the first in Turkey which can test engines of over 13 liters capacity.

Enlargement of Ford Trucks’ global dealerships

As part of the Global Cargo enlargement strategy, we strengthened our structure both inland and abroad with the new Ford Trucks facilities. In 2014, we opened our first sales offices by establishing distributorships in Saudi Arabia and the United Arab Emirates.

Memorandum of Understanding for producing trucks in Russia

As well as a bodywork and chassis licensing agreement with JMC relating to chassis, bodywork and parts technology, we signed a memorandum of understanding with the Russian company Avtotor to cooperate for truck production

Opening of Turkey’s Biggest R&D Center

The story of our R&D, which began in 1961 with ten engineers, reached new levels in 2015 with about 1350 R&D engineers. Our Sancaktepe R&D center entered service with 1350 engineers at a single location, the biggest R&D center in the country. We provide service to a Ford global from our new center with more than half a century of experience in R&D.

Global Expansion Carried to North Africa

We opened a 4S truck facility in Morocco, establishing a Ford Trucks distributorship in our strategic expansion point of North Africa.

Start of Serial Production of New Generation of E6 Ecotorq Truck Engines

Serial production started of the new generation of Ecotorq truck engines, 100% developed by Ford Otosan engineering and with the intellectual and industrial property rights completely belonging to Ford Otosan. This new engine, which will give us a competitive advantage in the heavy commercial vehicle market, was introduced to the market along with a new generation of Ford Trucks models. Ford Otosan, as the only Turkish automotive company with the capacity to completely design and produce a vehicle including the engine, won the Technology Grand Prize in June 2016 with the Ecotorq engine, representing the highest levels of our R&D skills.

Ford Otosan – Turkey’s Export Champion

In 2015 we became Turkey’s export champion with an export income of 3.9 billion dollars. At the same time we succeeded in being automotive sector champions for five successive years.

Ford Trucks continued its international expansion in Europe

Ford Trucks accelerated its global expansion with the opening of three new dealers in three European countries. Following the opening of the largest European 4S facility in Bucharest, Romania with distributor Cefin Trucks, Ford Trucks also signed new partnership deals and opened facilities in Hungary with distributor Delta Truck, and in Bulgaria with distributor Bulavto Holding. With these openings in Eastern Europe, Ford Trucks continues to move forward in line with its international growth plans.

Decision to invest $52 million to meet growing demand

Aiming to meet the growing demand in global markets, and Europe in particular, we have decided to invest $52 million to increase the production capacity. As a result of this investment, the total annual production capacity of 415,000 vehicles in the three plants will be increased to 455,000 by the end of September 2018.

Castrol Ford Team Türkiye won the European Rally Championship

Castrol Ford Team Türkiye, competing in the European Rally Championship, which is organized by FIA (Federation Internationale de l'Automobile) and consists of eight races, including four on asphalt and four on gravel, brought home the first ever European team championship title.

“2019 International Truck of the Year Award” goes to the new Ford Trucks tractor F-MAX, developed by Ford Otosan

The new Ford Trucks tractor F-MAX, which was designed, developed and producd by Ford Otosan, won the “2019 International Truck of the Year” award. The prestigious award of the heavy commercial vehicles industry was presented by Gianenrico Griffini, chairman of the International Truck of the Year (IToY) jury, to Haydar Yenigün, Ford Otosan General Manager at the Ford Trucks stand at IAA Commercial Vehicles 2018.

Platooning technology R&D agreement between Ford Otosan and AVL

We signed an important agreement with AVL Research and Engineering on “Platooning” technology that will lead the transition to autonomous driving technologies in the transportation sector as a first in Turkey.

World Economic Forum included Ford Otosan in the Global Lighthouse Network

Ford Otosan’s Gölcük plant was named a Lighthouse Factory by the World Economic Forum (WEF) and added to the “Global Lighthouse Network”, which aims to identify and spread the best examples in the "Industry 4.0" We are the first automotive company in Turkey and the Ford Universe, and one of the four worldwide to join this network.

Ford Otosan and AVL Take an Important Step towards Autonomous Transportation

Initial road tests for the “Platooning - Autonomous Truck Convoy” project, which will enable smart mobility, reduced carbon emissions, reduced fuel consumption and improved road safety, have been successfully completed on F-MAX, the new tractor of Ford Trucks.

Ford Trucks started its organizational structuring in Western Europe with Spain, Italy and Portugal

We completed the organizational structuring in Central and Eastern Europe, and moving to Western Europe, the champion league of the truck market, with our first facilities in Spain, Portugal and Italy. Thanks to these openings, our Ford Trucks brand reached 43 countries in international markets.

Ford Otosan started to production of Turkey’s first and only local plug-in hybrid electric commercial vehicle Ford Custom PHEV

Ford Transit Custom PHEV, a first for Turkey, with Plug-in Hybrid technology (PHEV) that enables electric motors and internal combustion engines to work together, is ready for mass production with its new production line in Kocaeli plants, biggest commercial vehicle production base in Europe. Ford Custom Plug-in Hybrid (PHEV) received 2020 International Van of the Year (IVOTY) award.

Ford'un tam elektrikli ilk ticari aracı E-Transit ve Batarya Montaj Yatırımı

Ford'un tam elektrikli ilk ticari aracı E-Transit ve Batarya Montaj Yatırımı

Türkiye’nin en büyük otomotiv yatırımını

Türkiye’nin en büyük otomotiv yatırımını

Ford Otosan’dan kurumsal girişim sermayesi şirketi Driventure

Ford Otosan’dan kurumsal girişim sermayesi şirketi Driventure

Ford Trucks Bayı Açılışları, Belçika, Lüksemburg ve Avrupa nın en büyüğü Almanya pazarında

Ford Trucks Bayı Açılışları, Belçika, Lüksemburg ve Avrupa nın en büyüğü Almanya pazarında

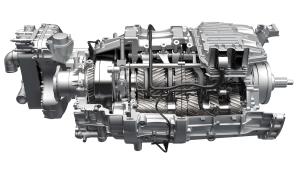

Türkiye’nin ilk ve tek yerli şanzımanı

Türkiye’nin ilk ve tek yerli şanzımanı

Ford Otosan tarafından Türkiye’de üretilen Transit Custom’a Euro NCAP’den ‘Altın’ ödül

Ford Otosan tarafından Türkiye’de üretilen Transit Custom’a Euro NCAP’den ‘Altın’ ödül

Rakun Üretimi Başladı

Rakun Üretimi Başladı

Craiova Plant joined the Ford Otosan organization.

Ford Otosan became a multinational company manufacturing in Europe following the acquisition of Ford’s Craiova Plant in Romania. As a result, total annual production capacity exceeded 900,000 units.

The Legendary Transit Electrified

E-Transit, Europe's most powerful and Turkey's first electric commercial vehicle, was rolled off the assembly line at our Kocaeli Plants, which generates 100% of its electrical energy from renewable sources. E-Transit, the first reward of the 2 billion Euro investment plan, has also become a significant milestone in our electrification journey. With this, Ford Otosan has now become Ford's production base for electric commercial vehicles in Europe. Ford E-Transit received Gold Award from the independent vehicle safety organization Euro NCAP for its Advanced Driver Assistance Systems.

Ford Turkey brings the country’s first digital studio to the Metaverse

Ford Otosan brought Digital Studio to the Metaverse as part of the "Live the Future Today" discourse, breaking new ground in the automotive industry. With Ford Digital Studio, we offered our customers the opportunity to review selected Ford models at their convenience.

'The Future. Now' to transform Turkey's automotive ecosystem's future

With the vision of "The Future, Now," we announced our long-term sustainability goals that will transform the future of Turkey's automotive ecosystem in a variety of areas ranging from climate change to waste management and circular economy, from diversity and inclusion to volunteering projects that will benefit social welfare.

Ford's global business model Ford Pro is now in Turkey

We introduced Ford Pro, an innovative business model aimed at providing solutions to commercial customers of all sizes to increase productivity and lower operating costs. With Ford Pro, we took an important step toward making it easier for fleets to transition from internal combustion engine vehicles to electric vehicles.

The electrification journey of Ford Otosan in Romania

By breaking new ground, we acquired the Craiova factory in Romania, which is critical to Ford's electrification strategy, and took over production of the Puma and Ecosport models. Craiova's manufacturing capacity, combined with our extensive experience in electrification, commercial vehicle design, and engineering, has propelled our operations to a global scale.

100% electric truck developed and manufactured in Turkey

At IAA Transportation in Hannover, we unveiled our first all-new %100 electric truck, designed and manufactured entirely by Ford Otosan engineers and rolled off the assembly line at our Eskişehir factory. This has become one of the pillars of our transformation journey with zero-emission, connected, and autonomous technologies, which began with the 'Generation F movement' in heavy commercial vehicles.

Yeniköy Plant reopened with 2.5 times increased capacity.

Yeniköy Plant was redesigned and reopened as a key milestone of Ford Otosan’s €2 billion investment plan, increasing annual capacity to 405,000 units. A flexible manufacturing architecture enabling both electric and internal combustion vehicles to be produced on the same line was implemented

E-Transit Custom production started.

The fully electric version of Europe’s best-selling commercial vehicle began production in Yeniköy, while electric Courier models started production in Craiova

Ford Transit Courier and Tourneo Courier rolled off the line.

The next-generation Ford Transit Courier and Tourneo Courier, engineered and produced by Ford Otosan, rolled off the production line at the Craiova Plant, their sole global production hub.

Umutkent – Gelecek Hayalim Centers were launched.

Following the February 6 earthquakes, “Umutkent – Gelecek Hayalim” centers were established in Hatay, Adıyaman, and Kahramanmaraş. In five container cities comprising 5,000 units, education facilities, technology workshops, libraries, and social spaces were created. Technical training and employment support programs were launched for earthquake survivors.

Production of Volkswagen’s 1-ton commercial vehicle began under the Ford–VW strategic partnership.

Within the scope of the global partnership, production of Volkswagen’s new-generation 1-ton commercial vehicles (New Transporter) started at Ford Otosan’s Kocaeli facilities.

The Gelecek Hayalim Project expanded to support women in STEM fields.

The Gelecek Hayalim project evolved into a comprehensive social transformation model, targeting 100,000 women in STEM education by 2026. The Holistic Empowerment Program, covering coding, data analytics, and robotics, was implemented

The F-Line Series was launched.

The new Ford Trucks F-LINE series was introduced with distinctive design, connected vehicle technologies, and advanced safety features.

The new Ford Transit Custom won IVOTY.

The next-generation Transit Custom, produced at Yeniköy Plant, received the 2024 International Van of the Year (IVOTY) award

Production of fully electric Puma Gen-E, E-Transit Courier, and E-Tourneo Courier started.

Serial production of Ford Puma Gen-E, Ford E-Transit Courier, and Ford E-Tourneo Courier began at the Craiova Plant, completing the electrification of Ford Otosan’s vehicle portfolio

A Joint Development Agreement was signed between Ford Otosan and Iveco.

A cabin development partnership was established with Iveco to enhance cost efficiency and technological advancement in the heavy commercial vehicle segment.

The new F-MAX and Ecotorq Gen2 were introduced.

Second-generation Ecotorq engines with improved fuel efficiency and the new-generation Ford Trucks F-MAX series entered production.

Ford Otosan became the first automotive manufacturer listed in the WEF Quantum Application Hub.

Ford Otosan became the first automotive company globally to enter the World Economic Forum’s Quantum Application Hub list, leveraging quantum technologies in logistics routing and production processes.

Yeniköy Plant was selected as a Global Lighthouse.

The World Economic Forum selected Yeniköy Plant as a Global Lighthouse in recognition of its Industry 4.0 and digital transformation excellence

The foundation of Vehbi Koç Foundation Semahat Arsel Primary School was laid.

In collaboration with the Vehbi Koç Foundation, the foundation of the 35-classroom Vehbi Koç Foundation Semahat Arsel Primary School was laid in Gölcük

Turkiye’s Export Champion for 10 consecutive years.

Ford Otosan achieved Turkey’s export leadership in goods exports for the 10th consecutive year

Gelecek Hayalim reached its social impact target.

Through its STEM-focused initiatives, Gelecek Hayalim reached 115,000 women and girls, enhancing technical competencies and reporting measurable social impact.

First vehicle delivery by rail between Craiova and Kocaeli.

As part of sustainable logistics targets between Craiova and Kocaeli plants, the first vehicle delivery was completed by rail, marking a strategic step toward the 2050 carbon neutrality goal.